The first layer is always the biggest problem because if it is not perfect it is going to be a mess. The nozzle has to drop the filament like an elipse shape (not too flat, not too circle shape) Now we have to calibrate the distance from the tip of the nozzle and the bed sheet:

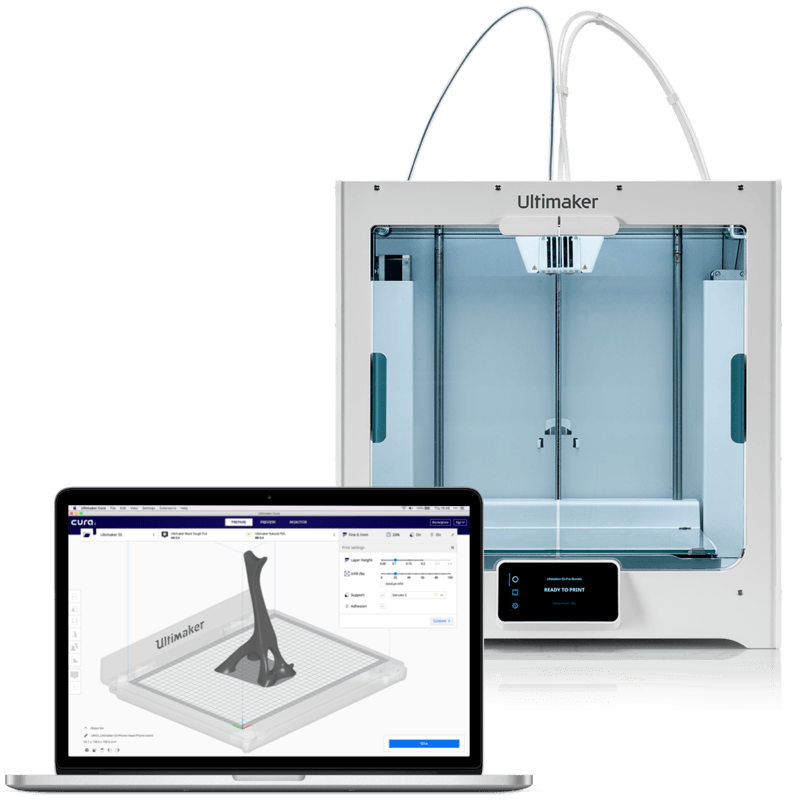

Remove the heat bed > place a piece of paper under the nozzle We will use wizard mode (calibrates all xyz): guides you through: Press the button to load filament and push it a bit from aboveĬALIBRATING MACHINE (everytime you move it around or you change something in order to check everything is in place) ¶ Push and it will start preheating, when it beeps it it heated PLA: nozzle will be 215 degrees/ bed temperature 60 Tell the machine which filament I am using: machine is interested in the temperature of the nozzle To get the filament to the nozzle you have to heat it up 1,75mm ->0,4mm You push the filament till it stops (limit) You cut material in 45 degrees before inserting the filament. Under extrude(you push less material through the nozzle that is needed) allows for flexible filament = nice mesh (cool designs)Īt the lab we also have flexible filaments, wood filaments, cork filaments, PVA filament (lower temperatures than PLA), solvable filament (dissolves in water, acts like a moulding), lipstick red PLA, high temperature filament(to undergo high temperature setting), iglidur (High wear resistance, complies with the fire prevention requirements of the FAA, lubrication-free and maintenance-free, higher temperature resistance up to 180☌), … PLA: biodegradable (corn based), quite sturdy, but also quite easy to break Ultimaker: less tweaking, less chance of making mistakes, less fancy possibilities

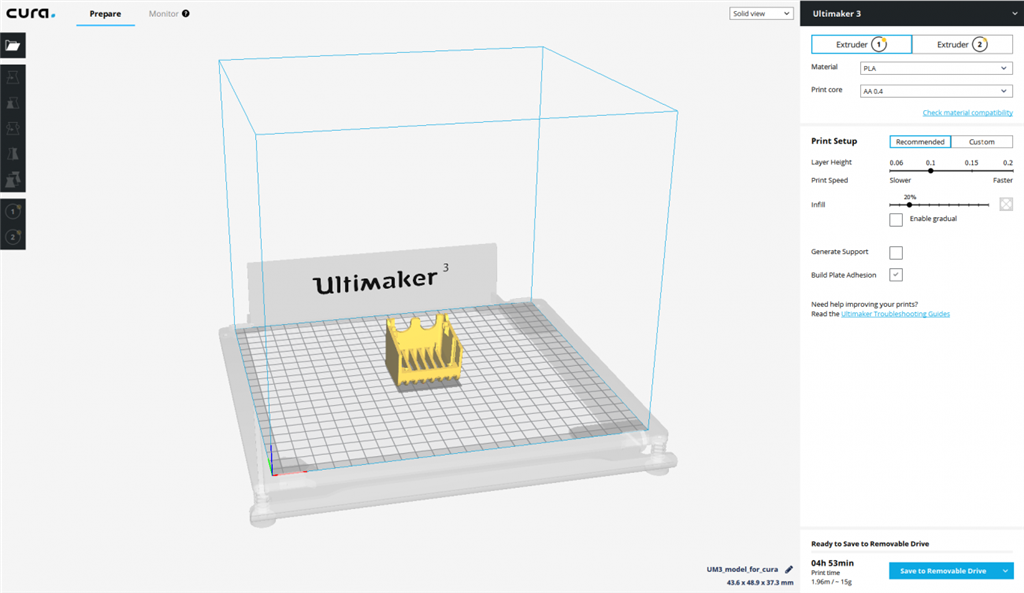

Ultimaker cura 4.7 download software#

The nice thing of Prusa is that you can tweak a lot of the settings in software and machine, but you can also make more mistakes. The filament is getting fluid and comes out of the nozzle. Tube for guiding the filament into the gears that are connected to the central motor Left side has a board(Arduino board with some H bridges on top of it to control the gears ) to control the PrusaĪnother gear in the printer head for the filament: The protection case is done with IKEA table(6 euros x2) + printed joints. It has very good improvements, mainly in the printer head. Included your original design files for 3D printing (both CAD and common format for 3D printing)ĭOUBT: Define cannot be easily made subtractivelyĪnswer: Your model has undercuts), overhangs, nested parts, meshes etc.ĭOUBT: What is a common format for 3D printingĪnswer: STL, OBJ or 3MF (please make your file small for the repository, compress reduce etc.)ĭOUBT: Should I include my scanned file(s)Īnswer: Not necessary, files can be very large LEARNING ABOUT THE 3D PRINTING MACHINES AT DEN WAAG: ¶Īt the FabLab we have a 3D Printer : Prusa i3 mk3 Identify the advantages and limitations of 3D printingĪpply design methods and production processes to show your understanding of 3D printing.ĭemonstrate how scanning technology can be used to digitize object(s)Įxplained what you learned from testing the 3D printersĭocumented how you designed and made your object and explained why it could not be easily made subtractivelyĭocumented how you scanned and prepared an object (for 3D printing) 3D scan an object, try to prepare it for printing (and optionally print it) Individual assignment: Design and 3D print an object (small, few cm3, limited by printer time) that could not be easily made subtractively. Document your work and explain what are the limits of your printer(s) (in a group or individually.

Group assignment: Test the design rules for your printer(s). Week 05: 3D scanning and printing ¶ Assignments: ¶ Week 17: Invention, Intellectual Property and Business Models

Week 14: Interface and application programming Week 13: Embedded networking and communications Week 09: Mechanical design, machine design LEARNING ABOUT THE 3D PRINTING MACHINES AT DEN WAAG:ĬALIBRATING MACHINE (everytime you move it around or you change something in order to check everything is in place)įIRST ATTEMPT: no filament was coming out of the filament. Week 01: Principles and practices and project management

0 kommentar(er)

0 kommentar(er)